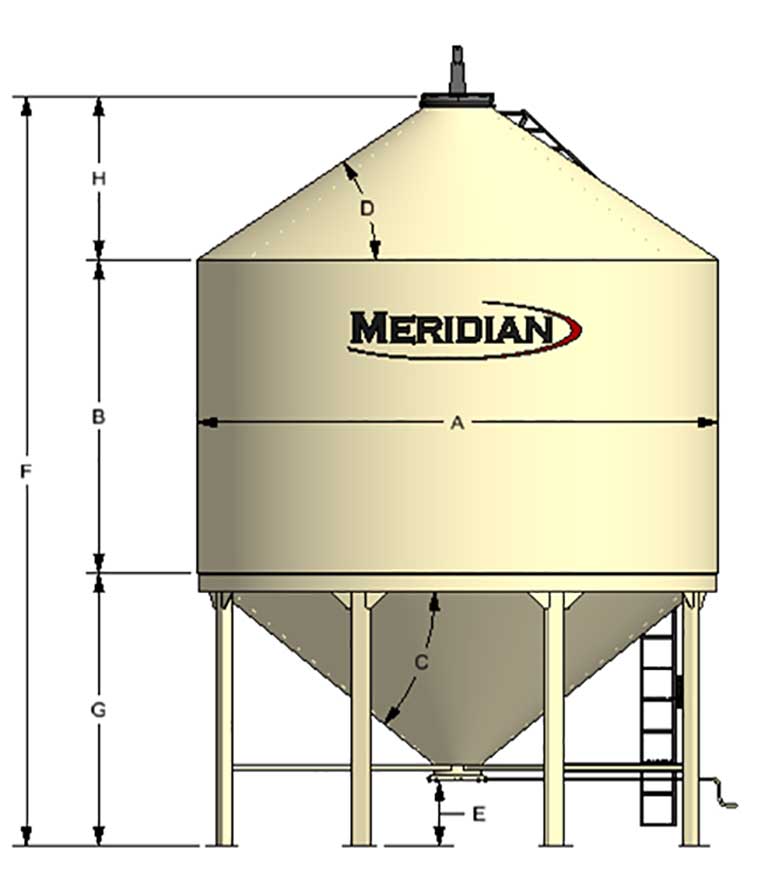

Multi-purpose Silos

Meridian Multi-Purpose SmoothWall Silos are built with industrial gauge steel and designed for a variety of commercial applications. These silos are build with an interior and exterior powder coating to ensure long life and performance. Meridian offers a variety of powder coating options including zinc and epoxies to ensure years of trouble-free storage, regardless of the commodity stored. Contact the industrial team today to learn more about using Meridian Multi-Purpose SmoothWall Silos for your next storage project.

Features Show / Hide more information

*Powder Coating is not available on all sizes and in all regions. systems

Applications Show / Hide more information

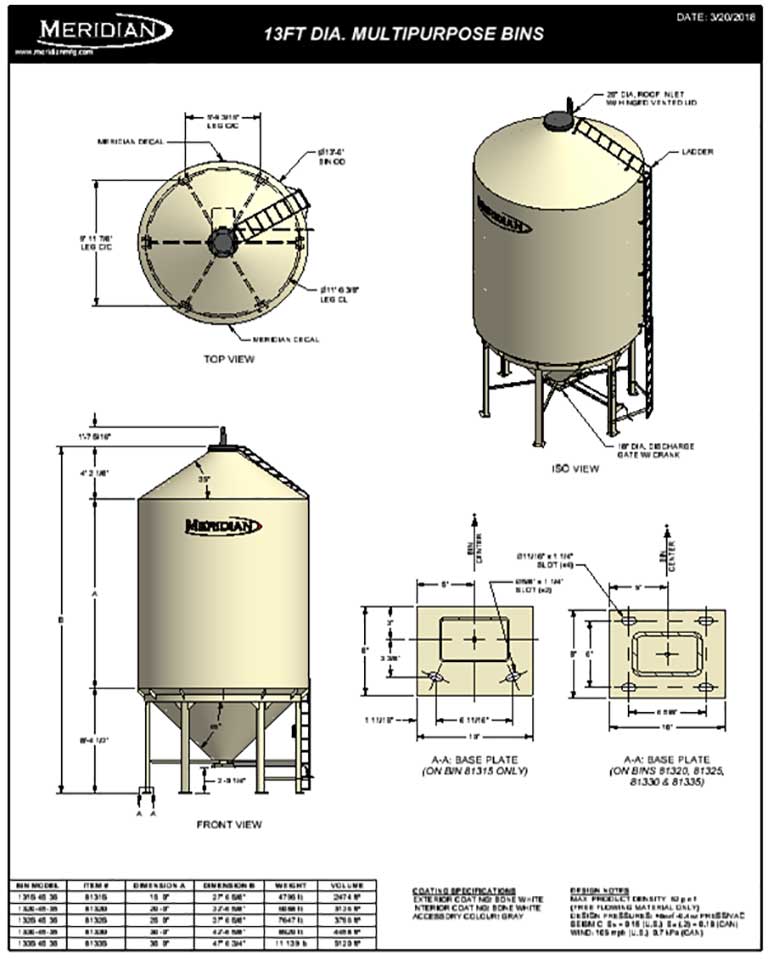

Specifications Show / Hide more information

Fertilizer Tanks:

Save time, money and become more efficient by storing your liquid fertilizer with a Meridian Stainless Steel Tank. Meridian tanks are the ideal solution to store your fertilizer on your operation, giving you instant access to your commodities and allowing you to purchase and stockpile fertilizer when prices are competitive. Built with 304 grade stainless, these flat bottom tanks undergo a wash and treatment system to remove any particles that may be left on the surface, followed by back welding interior seams and then pressure tested. They come standard with features such as a 24’’ manway for easy access, easy read liquid sight gauge, and more.

STANDARD FEATURES:

- 304L stainless steel construction

- 24” manway for easy access to interior of tank

- 4” vented dome cap

- 10 degree slope on dome

- Two 4” FPT discharge and recirculating ports

- Volume labeled sight gauge

- ¾” sight gauge tube with stainless auto shutoff valve

- Lifting Lugs

- 2 year manufacturer’s warranty

- Min. 40 degree bottom cone and 35 degree roof cone

- 24” clearance under the slide gate

- Retractable ladder

- Cover Plates w/ flanged inlets

- Hand rails

- Ladder Cages

- Rest platforms

- Perimeter Railing

- Fall Arrest System

- Manholes

- Catwalk Brackets

- Vacuum Vents

- Vent Pipes

- Flanged port for Level indicators

- View glasses

- Custom Paint colors and decals

- Industrial Paint upgrade

- Flanged discharges

- Rack & Pinion Gates

- Chisel Boot Transitions

- Various Btm clearances available

- Various Roof & Btm cone degrees available

| Model Number | Approx. Bushels | Cubic Feet | Imp. Tons | Metric Tonnes | Bin Height |

|---|---|---|---|---|---|

| 12′ Diameter Multi-Purpose – 45 Degree Bottom Cone | |||||

| 1205 | 806 | 949 | 29 | 27 | 16′-8″ |

| 1208 | 1095 | 1288 | 40 | 36 | 19′-8″ |

| 1210 | 1287 | 1514 | 47 | 43 | 21′-8″ |

| 1212 | 1479 | 1740 | 54 | 49 | 23′-8″ |

| 1215 | 1768 | 2080 | 64 | 58 | 26′-9″ |

| 14′-0″ Diameter Multi-Purpose – 45 Degree Bottom Cone | |||||

| 1410 | 1801 | 2146 | 67 | 60 | 23′-4″ |

| 1412 | 2060 | 2454 | 76 | 69 | 25′-4″ |

| 1415 | 2449 | 2914 | 90 | 82 | 28′-4″ |

| 1417 | 2708 | 3222 | 100 | 91 | 30′-4″ |

| 1420 | 3097 | 3683 | 114 | 104 | 33′-4″ |

| 15.5′ Diameter Multi-Purpose – 40 Degree Bottom Cone | |||||

| 15610 | 2241 | 2636 | 82 | 74 | 23’-9” |

| 15612 | 2526 | 3010 | 93 | 85 | 25′-9″ |

| 15615 | 3003 | 3575 | 111 | 101 | 28′-9″ |

| 15617 | 3320 | 3952 | 123 | 111 | 30′-9″ |

| 15620 | 3796 | 4515 | 140 | 127 | 33′-9″ |

| 15625 | 4589 | 5455 | 169 | 153 | 38′-9″ |

| 15630 | 5383 | 6396 | 198 | 180 | 43′-9″ |

| 16′ Diameter Multi-Purpose – 40 Degree Bottom Cone | |||||

| 1610 | 2410 | 2831 | 88 | 80 | 23′-11″ |

| 1612 | 2751 | 3233 | 100 | 91 | 25′-11″ |

| 1615 | 3264 | 3835 | 119 | 108 | 28′-11″ |

| 1617 | 3606 | 4237 | 131 | 119 | 30′-11″ |

| 1620 | 4119 | 4837 | 150 | 136 | 33′-11″ |

| 1625 | 4973 | 5839 | 181 | 164 | 38′-11″ |

| 1630 | 5828 | 6842 | 212 | 192 | 43′-11″ |

| 18′ Diameter Multi-Purpose – 40 Degree Bottom Cone | |||||

| 1810 | 3161 | 3719 | 115 | 105 | 25′-6″ |

| 1815 | 4242 | 4991 | 155 | 140 | 30′-6″ |

| 1820 | 5324 | 6263 | 194 | 176 | 35′-6″ |

| 1825 | 6405 | 7536 | 234 | 212 | 40′-6″ |

| 1830 | 7488 | 8809 | 273 | 248 | 45′-6″ |

| Model Number | Approx. Bushels | Cubic Feet | MT (Fertilizer) | MT (Feed) | Bin Height |

|---|---|---|---|---|---|

| 12′ Diameter Steep Cone Series – 55 Degree Bottom Cone | |||||

1208-55 | 1178 | 1382 | 39 | 25 | 22′ |

1210-55 | 1371 | 1607 | 45 | 29 | 24′ |

1212-55 | 1563 | 1833 | 52 | 33 | 26′ |

1215-55 | 1851 | 2171 | 61 | 39 | 29′ |

| 14′ Diameter Steep Cone Series – 55 Degree Bottom Cone | |||||

1410-55 | 1928 | 2297 | 65 | 42 | 26′ |

1412-55 | 2187 | 2605 | 73 | 47 | 28′ |

1415-55 | 2576 | 3065 | 86 | 56 | 31′ |

1417-55 | 2835 | 3372 | 95 | 61 | 33′ |

1420-55 | 3224 | 3833 | 108 | 70 | 36′ |

| 15.5′ Diameter Steep Cone Series – 55 Degree Bottom Cone | |||||

15.510-55 | 2447 | 2917 | 82 | 53 | 28′ |

15.512-55 | 2765 | 3293 | 93 | 60 | 30′ |

15.515-55 | 3242 | 3858 | 109 | 70 | 33′ |

15.517-55 | 3559 | 4235 | 119 | 77 | 35′ |

15.520-55 | 4036 | 4800 | 135 | 87 | 38′ |

15.525-55 | 4830 | 5741 | 161 | 104 | 43′ |

15.530-55 | 5621 | 6678 | 188 | 121 | 48′ |

| 16′ Diameter Steep Cone Series – 55 Degree Bottom Cone | |||||

1610-55 | 2638 | 3144 | 88 | 57 | 28′ |

1612-55 | 2976 | 3545 | 100 | 64 | 30′ |

1615-55 | 3484 | 4147 | 117 | 75 | 33′ |

1617-55 | 3823 | 4548 | 128 | 83 | 35′ |

1620-55 | 4330 | 5150 | 145 | 93 | 38′ |

1625-55 | 5177 | 6153 | 173 | 112 | 43′ |

1630-55 | 6019 | 7152 | 201 | 130 | 48′ |

Additional Options Show / Hide more information

Meridian’s Stainless Steel Bucket Elevators are designed to provide reliable durability and maximum throughput with a wide range of options and accessories built for fertilizer applications.

Features

- Stainless Steel Construction

- From 50 to 700 Tonnes/Hr

- Discharge Heights up to 200’

- Twin Trunking w/

Weather-Tight Design - Easy Clean-Out Boot w/

Winged Pulley & Access

Doors

Options

- Stainless or Mild Steel

Spouting - Stainless Steel Distributors

- Ladders, Cages and Rest/

Work Platforms - Support Towers

- Automation/Monitoring

Stainless Steel U-Trough Augers can be used for blending, overhead, receiving or transfer applications. Meridian Fertilizer U-Trough Augers feature a Stainless Steel u-trough body and auger flighting, Meridian U-Trough Augers are built to last.

Features

- Stainless Steel body &

flighting - Hanger Bearings

- 6” – 16” models

Options

- Intake & Discharge Options

- Built to CEMA Standards

- Mounting Equipment

- FWD and REV capability

(for cycling fertilizer storage)

Meridian’s Stainless Steel Chain Conveyors can be used for receiving, transfer or load-out. With a fully-enclosed design with a self-cleaning tail, Meridian Chain Conveyors are versatile and maintenance friendly.

Features

- Fully Enclosed Design w/

Stainless Steel Construction - From 45 to 570 Tonnes/Hr

- 0-45° Inclines

- Self-Cleaning Tail Section

- UHMW Paddles

Options

- Inlet Hoppers

(drive-over, wide, narrow,

flanged, etc.) - Discharge/Transition Options

(ie. flush-mounted slide gate) - Mounting Equipment

- Automation/Monitoring

Meridian Metering Augers allow you to precisely measure product as it is discharged from a bin to ensure proper blending amounts. Our Metering Augers are controlled via an Automated Operating System.

Features

- Stainless Steel construction

- Twin-Flight Design for low RPM

- 6”, 8”, 10” and 12” Models

Options

- Transition options for

Under-Bin mounting

Stainless Steel Utility Augers are designed for low-volume, short-jump applications where fertilizer must be transferred quickly but at very short distances. Meridian Stainless Steel Utility Augers are built to handle fertilizer applications. Meridian offers a range of accessories built to enhance your fertilizer system. These accessories include:

Features

- Stainless Steel Slide Gates

- Stainless Steel Transitions

- Stainless Steel Valves

Options

- Stainless Steel Spouting

- Stainless Steel Distributors

Accessories & Options Show / Hide more information

Warranty Show / Hide more information

To learn more, call your local dealer.